6 Reasons Crepe is the New Kraft

Some sources on Wikipedia, date the invention of paper back as early as 2nd century BC in China. Over thousands of years, the process has

Some sources on Wikipedia, date the invention of paper back as early as 2nd century BC in China. Over thousands of years, the process has

Over the last ten years, the Peoria Mill has taken many steps to improve the quality of the paper, improve the efficiency of the paper

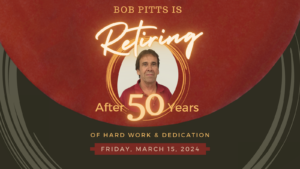

A Half-Century of Dedication: Celebrating Bob Pitt’s Remarkable Career Journey In the rich history

Meet Bo, our Chief Morale Officer and youngest member of our team. Bo joined our team in February of 2022 at the age of 10 weeks. Bo enjoys meeting and greeting employees and visitors throughout the day and of course getting his treats from his humans. Bo enjoys being part of our team as much as our team enjoys Bo.

10 years in the paper industry

Brian began working at Ivex Specialty Paper in May of 2014. He is skilled at just about every job on the floor from extra hand to boiler relief operator. In his current role at Ivex, he works diligently to maintain and ensure good paper is produced for our customers. Safety is also a huge priority for Brian. He helps and guides his team to always stay safe while producing a quality product. Brian says he’s excited to continue growing and learning as he overcomes new daily challenges. He sees his Ivex team as family and strives to be the best he can for them and the company.

Contact Brian via phone at (309)-686-3830 x7124

• B.S. in Chemical Engineering, Worcester Polytechnic Institute

• Ph.D. in Paper Science, Georgia Institute of Technology

Adam began working at Ivex Specialty Paper in September of 2022. His previous experience includes various production and technical roles at ND Paper, including Senior Production Engineer. In his current role at Ivex, he focuses on new product development to maintain and improve quality for existing customers. In addition, he will work on advancing new grades for future customers. Adam says he’s excited to work with Ivex’s interesting paper machine because it’s capable of such a diverse range of potential products.

Contact Adam via phone at (309)-686-3830 x7140

Michelle spent the early part of her career in the engineering and start-up worlds at B2B technology companies ranging from energy to educational software. As our Director of Marketing, she brings this entrepreneurial, growth mindset to help us connect with our current and soon-to-be customers. She enjoys discovering creative ways to share our stories with the world and says she is constantly learning new things about paper from our long-time team members.

Dan has over 28 years of experience in Maintenance and Engineering, with over 20 years of that in senior management roles. His background includes automotive, steel manufacturing, and fermentation. As the Maintenance and Engineering Manager, it is Dan’s responsibility to schedule maintenance and equipment PM’s, procure parts, oversee project work from concept to completion, manage building maintenance and schedule and oversee contractor work. He says he has found the staff here to be very knowledgable and professional and looks forward to spending a long career learning from, as well as working with, the team at Ivex.

Contact Dan via phone at (309)-686-3830 x7129

Chris has been in the paper industry for the past 28 years, the last 18 years being with Ivex, and the last 10 of those years as a shift supervisor and machine superintendent. His main responsibilities are scheduling of the mill employees, ensuring all personnel are working safely and responsibly, maximizing machine output while upholding quality, overseeing the mill’s effluent costs and maintaining all data. Chris has completed a color school class through XRITE to expand his knowledge of our color control system at the mill as well. He says he enjoys working with the entire team at Ivex on all the daily challenges and opportunities that come our way.

Contact Chris via phone at (309)-686-3830 x 7124

Paul has been working at the Peoria Mill for 32 years. He started as an extra man and worked his way up to Customer Service Manager. He says every day can bring a new challenge and his favorite part of working here is learning from each challenge as a team. Additionally, the friendships and loyalties he’s found here make this a great place to work.

Contact Paul via phone at (309)-686-3830 x 7114

Eric has been with the mill for 16 years. He started as an extra hand working his way up on the paper machine and into a Shift Supervisor’s position. He’s held roles such as Chief Steward with the Union and member of the safety committee. As Shift Supervisor, his responsibilities include the safety of employees, performance, and the quality of the product. Eric says the parts of his role that excite him most are the group of people he gets to work with on a daily basis and the quality product they get to produce for customers.

Contact Eric via phone at (309)-686-3830 x 7124

46 years in the paper industry

Dave began working at Ivex Specialty Paper in April of 2016, as Technical Manager. In his role as COO, he is involved many aspects of keeping the mill running smoothly. Dave says he has enjoyed the opportunity to work with a group of people who truly care about the product they are producing, and the customers that they are serving.

Contact Dave via phone at (570)-295-2323

Cathy has had the benefit of working in the paper industry in many functional roles. Her deep technical knowledge comes from operational experience across mills and her leadership of process and product improvement initiatives. Her time in product development gave Cathy exposure to the marketing and sales side of the business and, combined with her operational experience, gives her a well-rounded approach to her current role at Ivex. She says she loves to help customers solve problems quickly by recognizing opportunities in our technical capabilities and delivering them in a way that makes sense for their businesses and ours!

Contact Cathy via phone at (920)-216-8606

47 years in the paper industry

Bill’s first job in the paper industry was in Alabama in 1977. This remarkable industry has taken him to Wisconsin, Alabama, New York, Pennsylvania, Virginia, Ohio, and finally to Ivex Specialty Paper in Peoria, Illinois. Bill has had the opportunity to work in wood yards, pulp mills, utility operations with boilers, turbines and evaporators as well as paper machines, coaters, and converting equipment of all shapes and sizes. He says the work is exciting for certain, but the people are really what makes it all worthwhile.

Contact Bill via phone at (920)-284-1665